Selecting the right sheet metal fabricator can make or break your project. Finding a reliable and skilled custom metal fabricator is crucial. This is whether you’re working on a small custom design or a large industrial construction.

To help you make informed decisions, we’ve compiled a list of common mistakes to avoid when choosing a sheet metal fabricator. Read on to learn how to ensure the precision and quality of your next project.

Let’s get you started!

Not Checking Experience and Expertise

Experience and expertise are essential when it comes to sheet metal fabrication. You want to work with a fabricator who has the necessary:

- knowledge

- skills

- techniques

That way, they can help bring your project to life. Ensure that the fabricator you choose has relevant experience in working with the type of materials and processes needed for your project.

Don’t be afraid to ask for examples of their previous work or client references. This will give you a better understanding of their capabilities and help you make an informed decision.

Overlooking Certifications and Quality Standards

Certifications and quality standards are crucial in the sheet metal fabrication industry. They demonstrate a fabricator’s commitment to providing high-quality products and services. Before choosing a fabricator, make sure they hold relevant certifications such as ISO 9001 or AWS D1.1.

Also, ask about their quality control processes and procedures. A reputable fabricator will have strict quality control measures in place. This helps them ensure the accuracy and precision of their work.

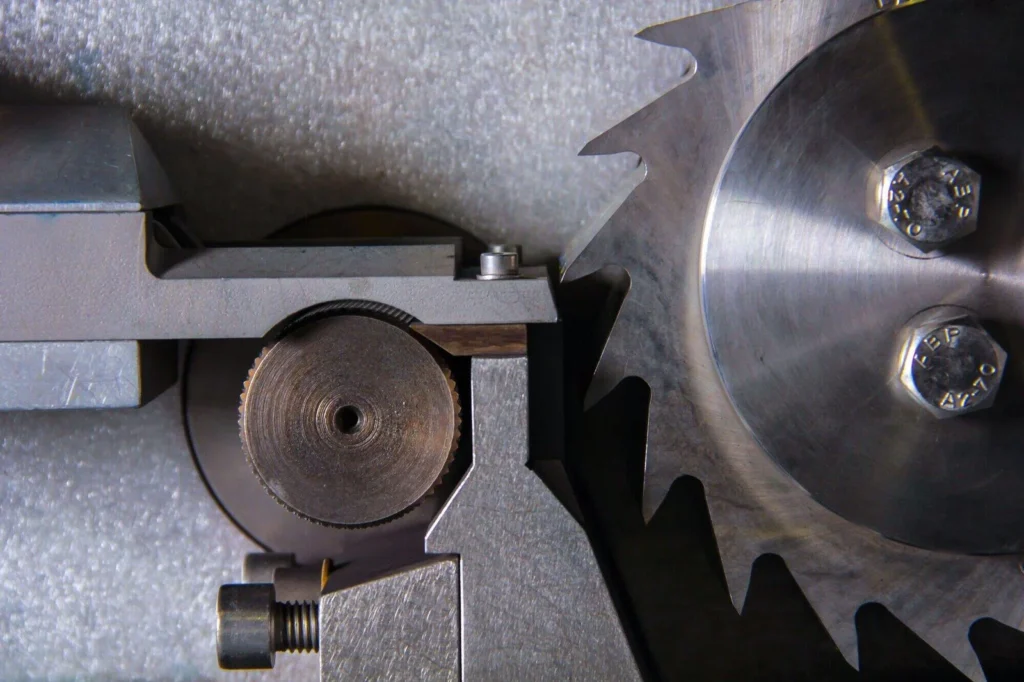

Ignoring Equipment and Technology

The type of equipment and technology used by a sheet metal fabricator can greatly impact the quality and efficiency of your project. Make sure to ask about what they use for fabrication, including:

- machinery

- tools

- software

A modern and well-maintained facility with advanced technology indicates that the fabricator is committed to providing top-notch services. Additionally, it shows their ability to handle complex projects with precision and accuracy. Take note that precision metal fabrication requires both skilled craftsmanship and advanced technology.

Not Evaluating Production Capacity

Before choosing a sheet metal fabricator, it’s vital to consider their production capacity. This includes their:

- workforce

- equipment

- turnaround time

You want to ensure that the fabricator has enough resources to handle your project within the specified timeline. Moreover, a fabricator with a large production capacity can also take on larger projects in the future if needed. This will save you from the hassle of finding a new fabricator for bigger projects.

Failing to Verify Material Quality

The quality of materials used in your project is crucial for its success. Make sure to ask the fabricator about their material sourcing process and quality control measures. A reputable fabricator will only use high-quality materials that meet industry standards.

You can also request material certifications. This can ensure that the materials used are exactly what you need for your project. This will save you from any potential delays or issues during fabrication.

If you ask custom metal fabricators, they will tell you that material selection is a crucial factor in the success of any project. From metal pemming services to welding processes, the quality of materials used plays a significant role.

Neglecting Lead Times and Delivery Schedules

It’s essential to discuss lead times and delivery schedules with your chosen fabricator. You want to ensure that they can meet your project timeline and deliver the finished product on time.

A reliable fabricator will have a well-organized production schedule and communicate any potential delays in advance. This will help you plan accordingly and avoid any last-minute setbacks.

Moreover, make sure to clarify any additional costs or fees for expedited services if you have a tight deadline. This will prevent any surprises and help you stay within your project budget.

Ignoring Customer Service and Communication

Communication and customer service are crucial for a successful project. Make sure to choose a fabricator who is:

- responsive

- transparent

- keeps you updated

They must do this throughout the fabrication process. A good fabricator will also listen to your needs and provide suggestions or solutions to any potential issues that may arise. This level of communication and attention to customer service ensures a smooth and satisfactory experience for both parties involved.

Not Considering Customization Capabilities

It’s essential to choose a sheet metal fabricator with customization capabilities. This allows for greater design flexibility and ensures that your project is tailored to your specific needs.

A fabricator with customization capabilities can also provide innovative solutions and suggestions. That way, they can help improve the functionality and appearance of your project. Don’t be afraid to discuss your ideas and requirements with the fabricator before starting the fabrication process.

Moreover, choosing a fabricator with customization capabilities can save you time and money in the long run. This is because they can handle all aspects of your project without outsourcing to multiple vendors.

Overlooking Cost vs. Value

It’s important to consider the cost vs. value when choosing a sheet metal fabricator. While it may be tempting to go with the cheapest option, keep in mind that quality and expertise come at a price.

Evaluate the fabricator’s capabilities, experience, and reputation before making a decision based on cost alone. It’s better to invest in a reputable and skilled fabricator who can deliver high-quality results rather than settling for lower quality and potentially facing costly issues down the line.

Skipping References and Reviews

Finally, don’t forget to ask for references and read reviews from previous clients. This will give you insights into the fabricator’s reputation, work ethic, and overall satisfaction of their customers.

Don’t hesitate to reach out to the references provided and ask about their experience working with the fabricator. It’s always better to hear from others who have firsthand experience rather than solely relying on the fabricator’s claims.

Know What to Avoid when Choosing a Sheet Metal Fabricator

Selecting the right sheet metal fabricator requires careful consideration and evaluation. By following these tips, you can ensure the success of your project.

By keeping these tips in mind, you can confidently choose a skilled and reliable sheet metal fabricator who will bring your project to life with precision and quality. So, don’t make these mistakes, and take your time to find the perfect fabricator for your next project!

Visit our blog page to read more topics. We do have more for you!