Do you want to make your grinding equipment last longer?

With some simple care and smart use, you can keep your machines running well for years. Regular check-ups, quick repairs, and using the machines the right way can save you time and money.

Also, using good quality parts and learning about new technology helps a lot. Follow these easy tips to keep your grinding equipment in great shape and avoid costly breakdowns. Ready to make your equipment last longer? Let’s get started.

Regular Maintenance

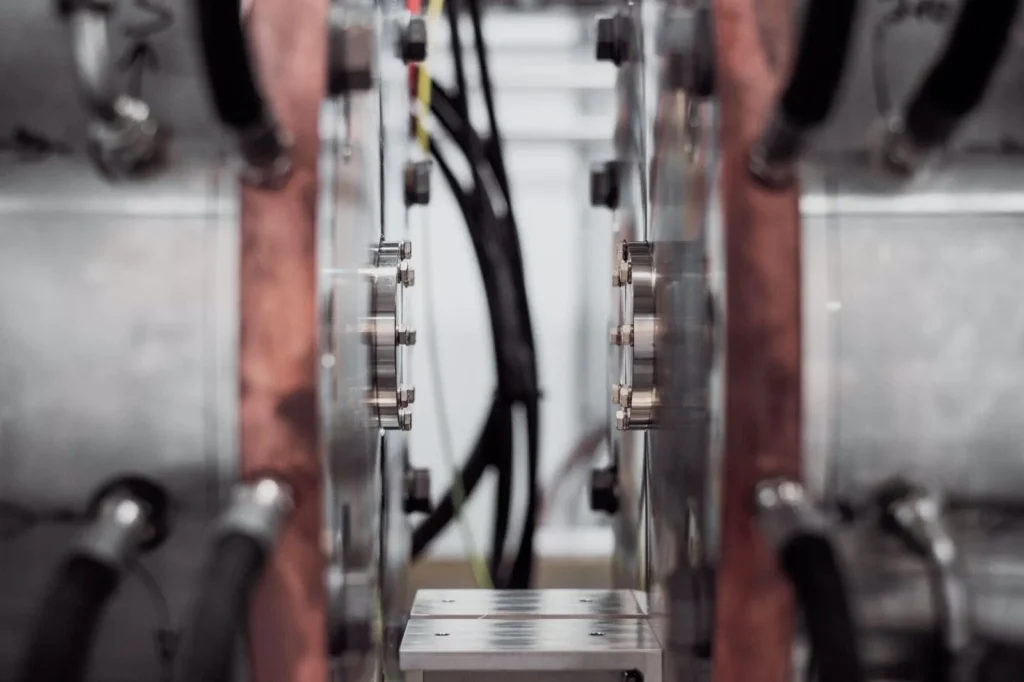

Want your grinding equipment to last longer? Regular maintenance is key. By taking care of machines like the Viking Centerless Grinder, you can avoid big problems. Check your equipment often to spot any wear and tear early.

Clean it regularly to remove dust and dirt that can cause issues. Make sure all moving parts are well-oiled to reduce friction and stop overheating. Calibrate the machine often to keep it working its best.

Train your staff to do these tasks correctly. With regular upkeep, you can extend the lifespan of your grinding equipment and ensure equipment longevity.

Use Quality Parts

Want your grinding equipment to last longer? Use quality parts. This is crucial for machinery preservation. Cheap or low-quality parts can wear out quickly and cause more damage. Invest in high-quality components that are designed for your specific machine.

This ensures better performance and reduces the need for frequent replacements. When parts fit well and work correctly, your equipment runs more smoothly and efficiently. Over time, this saves you money on repairs and downtime.

By using top-notch parts, you help extend the lifespan of your grinding equipment and keep it in good shape for years to come.

Proper Operation

To make your grinding equipment last longer, use it the right way. Train everyone on how to use the machines correctly. Follow the manufacturer’s instructions and don’t overload the equipment.

Using it wrong can cause wear and tear faster. Regularly check and adjust settings to keep the machine working well. Always use the right tools and materials to avoid extra stress on the equipment.

By using your machines properly, you can prevent costly repairs and downtime. Proper operation helps extend the lifespan of your grinding equipment and keeps it in good shape.

Timely Repairs

To make your grinding equipment last longer, fix problems quickly. If you see any issues, address them right away to stop them from getting worse. Small problems can turn into big, expensive repairs if ignored.

Check your machines often for signs of wear, like strange noises or poor performance. Replace worn-out parts promptly to keep the equipment running well. Following a maintenance schedule helps catch problems early.

By making timely repairs, you can reduce downtime, save money on major fixes, and keep your grinding equipment in good shape for a long time.

Keeping Your Grinding Equipment in Top Shape

Taking care of your grinding equipment is vital for keeping it running well for a long time. Use good parts, operate the machines correctly, and fix problems quickly to make them last longer.

Regular maintenance and quick repairs can stop big, costly issues before they happen. By looking after your equipment, you save money and boost productivity.

Keeping your grinding equipment in good shape ensures it works reliably and helps you avoid unexpected downtime. Follow these tips to get the most out of your grinding equipment for many years.

Did you find this article helpful? You can check out our website for more awesome content like this.